TTFC started in 1998 and since then has grown from strength to strength. A family company located in Wexford town, we pride ourselves on our reputation for high quality products and

excellent customer service. With a strong and established supply chain, TTFC’s production and delivery capacity is built to supply any size or type of project.

Residential developments, self builds, schools, hospitals, care homes and apartment blocks are all samples of completed projects in TTFC’s diverse portfolio. With the combined experience of TTFC’s design, manufacturing and management personnel, we have the resources to deliver any construction project.

One of the fundamental aspects of TTFC’s ethos is a commitment to customer satisfaction. Throughout the years, we have worked with numerous self-builders, architects, developers and contractors, building a reputation for providing high-quality timber framebuildings throughout Ireland and the UK and cultivating lasting relationships with these clients. At TTFC, we continue to research and develop our products and service to ensure the customers’ requirements are met and exceeded.

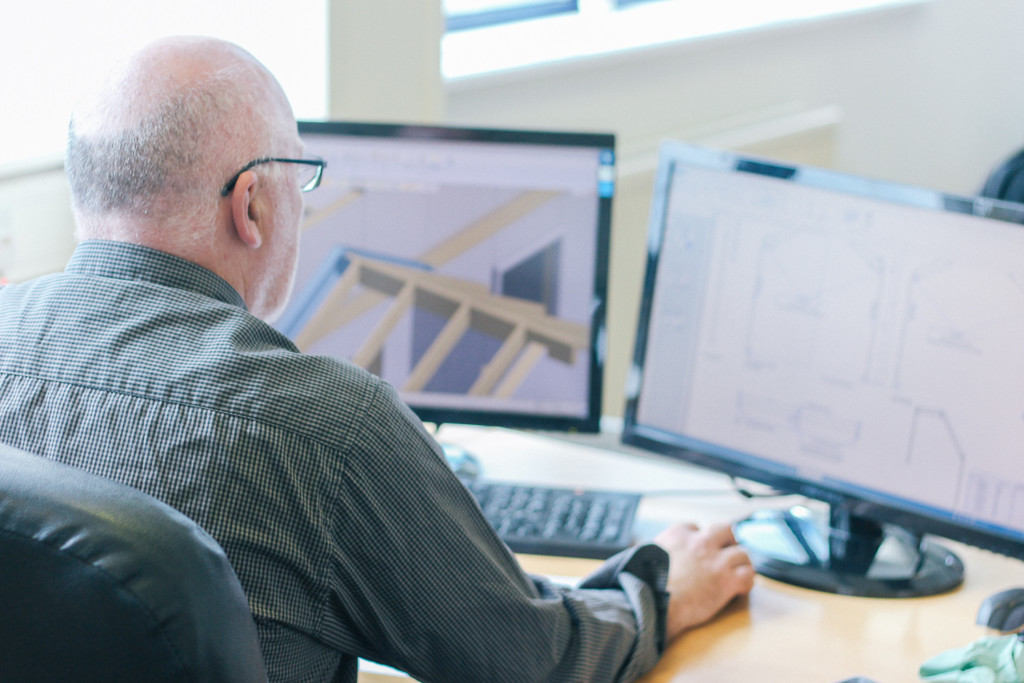

The Design Process

After we have agreed the contract, TTFC will engage an independent structural engineer to design all the structural elements of the timber frame and provide us with a full structural report. Your allocated TTFC project designer will take your drawings and design the timber frame replicating your plans. You will then be issued with a footprint drawing so your engineer can design the foundations. A 3D computer model of the building will be generated which will allow clear visualisation of the project at hand. You will then be issued with a full set of drawings to sign off to proceed with manufacturing.

The Manufacture Process

After sign off, we will begin preparations to begin manufacturing. The technician will begin generating production drawings and cutting lists, meanwhile the production team will order in all necessary materials and book a slot in the factory in line with an onsite start date. Once all is in place, we begin the manufacturing process, building it to the specification and design you have chosen. Firstly, we begin by cutting all the timber studs through our automatic saws to the correct size. Once complete we begin the assembly of the panels through a quality controlled production line ensuring accuracy. The panel are then stacked and loaded, ready for delivery.

After sign off, we will begin preparations to begin manufacturing. The technician will begin generating production drawings and cutting lists, meanwhile the production team will order in all necessary materials and book a slot in the factory in line with an onsite start date. Once all is in place, we begin the manufacturing process, building it to the specification and design you have chosen. Firstly, we begin by cutting all the timber studs through our automatic saws to the correct size. Once complete we begin the assembly of the panels through a quality controlled production line ensuring accuracy. The panel are then stacked and loaded, ready for delivery.

The Installation Process

Once we arrive on site, the completed wall panels and floor cassettes are carefully lifted and secured into place with a crane. The roof structure is then installed, ready for your roofer to complete. Once we have left site, M&E contractors can then move in on site to complete first fix. The final stages can then start, with the final insulation, air-tightness and plasterboard fitted, plastering can begin. Within weeks, you could be completing second fix elements and decorating.

Once we arrive on site, the completed wall panels and floor cassettes are carefully lifted and secured into place with a crane. The roof structure is then installed, ready for your roofer to complete. Once we have left site, M&E contractors can then move in on site to complete first fix. The final stages can then start, with the final insulation, air-tightness and plasterboard fitted, plastering can begin. Within weeks, you could be completing second fix elements and decorating.